In streetwear manufacturing, the key to high-quality clothing is a well-managed production process. Every hoodie, T-shirt, and jogger with a brand's identity follows a clear and organized process. This process balances creativity, precision, and craftsmanship

At Hangzhou Aiqi Clothing Technology Co., Ltd., a trusted custom streetwear manufacturer, we specialize in translating creative ideas into high-quality garments. This article explains how each step in production helps create the final streetwear product. It also shows how our process keeps quality and style consistent

Every great streetwear item starts with a concept — the story or identity you want your brand to express.

During the design phase, our team collaborates with clients to refine sketches, logos, and material selections. We focus on understanding:

The target audience (luxury, casual, or street culture-inspired)

Desired fit and silhouette (oversized, cropped, relaxed)

Key fabric and color choices

Tools like digital CAD design and mock-up visuals help clients preview the finished look before sampling.

The material defines not only the feel but also the functionality of a streetwear piece.

At Aiqi Clothing, we maintain long-term partnerships with fabric mills across China, ensuring access to premium materials like:

100% cotton fleece for hoodies

French terry for sweatshirts

Nylon blends for techwear

Organic and recycled fabrics for sustainable lines

Each fabric undergoes shrinkage, colorfastness, and durability testing before approval. This step ensures your final garments are comfortable, long-lasting, and on-brand.

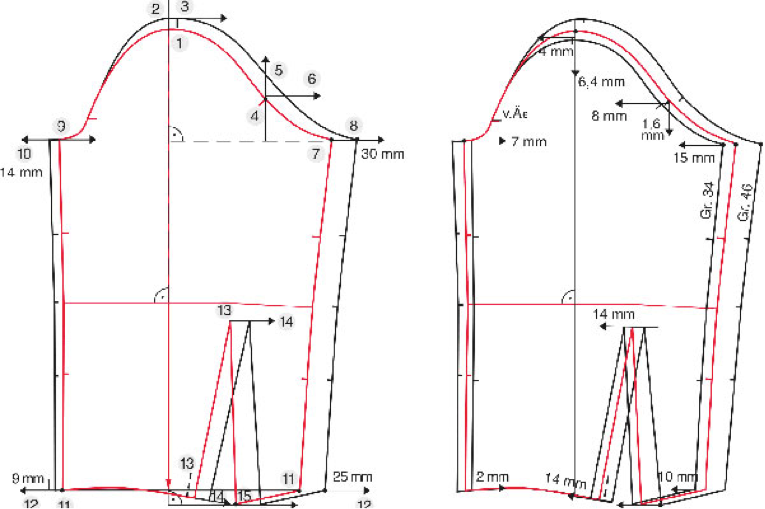

Once the materials are confirmed, the next step is pattern making. This means turning your design into technical templates. These templates show every cut and stitch

Our skilled pattern makers use digital pattern software (CAD) to ensure precision and scalability. Once the base pattern is approved, we start grading. This process changes the design into different sizes, like XS to XXL or custom sizes

This step ensures:

Accurate sizing consistency

Smooth production flow

Reduced fabric waste

Before mass production, we create a prototype sample — the first physical version of your design.

Clients can review this sample to confirm:

Fabric feel and color accuracy

Stitching quality

Fit, shape, and measurements

Logo placement and printing quality

We often go through 1–3 sample revisions to achieve perfection. This is the stage where creative vision meets technical execution, ensuring the garment fully matches the client’s expectations.

Once the sample is approved, bulk production begins. This phase combines automation and craftsmanship to produce hundreds or thousands of garments with consistent quality.

Key steps in production include:

Fabric cutting: Automated cutters ensure precision and efficiency.

Logo application: Depending on the brand’s design, we use screen printing, embroidery, DTF printing, or heat transfer.

Sewing & assembly: Skilled operators assemble panels, attach trims, and finish edges using industrial-grade machines.

At Aiqi Clothing, we do careful checks during production. This helps us find problems early. It reduces waste and keeps our results consistent

Before shipment, every item undergoes comprehensive quality control (QC).

Our QC specialists check for:

Stitch uniformity

Logo alignment and color accuracy

Sizing accuracy

Loose threads or material defects

Garments are then steam-pressed, folded, and packaged according to the brand’s standards. We can also use custom packaging. This includes branded tags, woven labels, and eco-friendly bags. These options can boost your product’s appeal in stores

The final step of the streetwear production process is logistics.

We coordinate with international shipping partners to deliver orders safely and efficiently. Depending on your location, we offer:

Sea freight for bulk orders

Air express for small batches or urgent deliveries

Our customer service team keeps in touch to ensure easy customs clearance and gather feedback. Production doesn’t stop when garments leave the factory

A structured, transparent production process ensures that:

Designs stay true to brand identity

Quality remains consistent

Costs are predictable and optimized

Delivery timelines are reliable

For streetwear brands, production efficiency directly impacts reputation. At Aiqi Clothing, we have a smooth workflow. This helps us produce high-quality products, control costs, and deliver on time. These are important for today’s fast-paced fashion market

With years of experience in custom streetwear production, Hangzhou Aiqi Clothing Technology Co., Ltd. supports both emerging and established fashion labels worldwide.

End-to-end OEM/ODM services

Low MOQ for startup brands

Flexible customization — fabrics, logos, packaging, labels

Experienced design consultation

Sustainability-focused production options

We blend creative freedom with industrial precision. This helps you turn your idea into high-quality streetwear that stands out in a busy market

The streetwear production process involves more than just stitching and printing. It is a creative journey from idea to finished product

Every stage, from design to QC, contributes to the authenticity, comfort, and style of the final item. It's important to work with a reliable manufacturer. This applies whether you have a small streetwear label or a large global brand. One option is Hangzhou Aiqi Clothing Technology Co., Ltd. ensures your designs become reality — efficiently, affordably, and flawlessly.